Sign up for our mail list by entering your email here. You'll get occasional notices of new blog entries, design tips and events.

26 September 2023

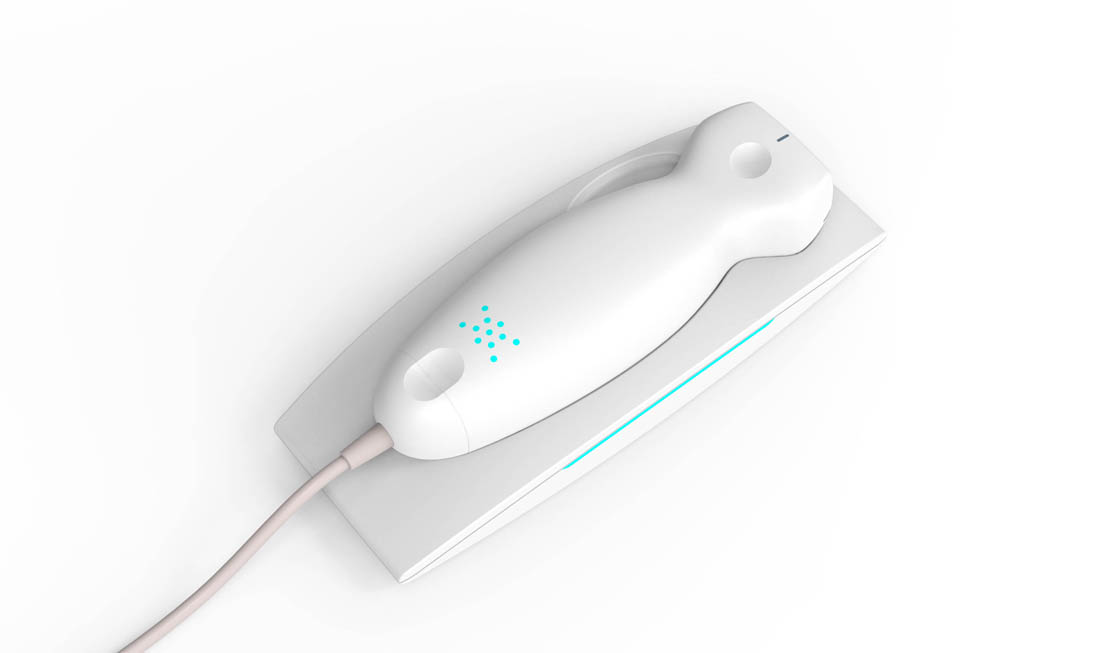

Exo Imaging announced the Exo Iris™, a pocket sized handheld ultrasound probe with advanced ultrasound silicon. We designed this probe working closely with the Exo Mechanical, Electrical and Clinical teams. The Iris is ergonomically designed with a balanced form, https://www.exo.inc/iris Services provided by EnMasse Design: Industrial design, surface and product development, graphics. Products Designed: Exo Iris, Wireless Charger, Duo Cable.  14 December 2022

2022 Good Design® Award from The Chicago Athenaeum: Museum of Architecture and Design. The Good Design Awards are celebrating 75 years of iconic design. Read about the Good Design Awards history.  12 September 2022

Oloid announced their family of mobile access solutions at GSX (Global Security Exchange) in Atlanta. The M-Tag family retrofits existing solutions with modern smartphone access capability. EnMasse provided the Industrial Design for the family of products including progressive design language, injection molded part design and product development services. http://www/oloid.ai http://www.enmassedesign.com/oloid.htm

3 May 2022

A project for Auris Health's Monarch platform (now J&J Ethicon division) we designed in 2019 received 510(k) clearance for Urology. Press release:

28 February 2022

Our client Pacira Biosciences (formerly Myoscience) launched their second generation Iovera Cyrotechnology device. The device uses innovative targeted cryoanalgesia to provide immediate and long lasting non-opioid pain relief. Our efforts were early stage concept explorations to improve the device user experience which included form development, ergonomics and balance, increased cartridge capacity to reduce cartridge changes (accomplished with easy to use, flip open door), an OLED screen with user interface design improvements, press on tips, various mechanism concepts and charging base with LED lighting. The charging base allows any tip to be installed while charging. Detailed design included injection molded part design, CMF, graphics and manufacturing liaison with off-shore suppliers.

29 September 2021

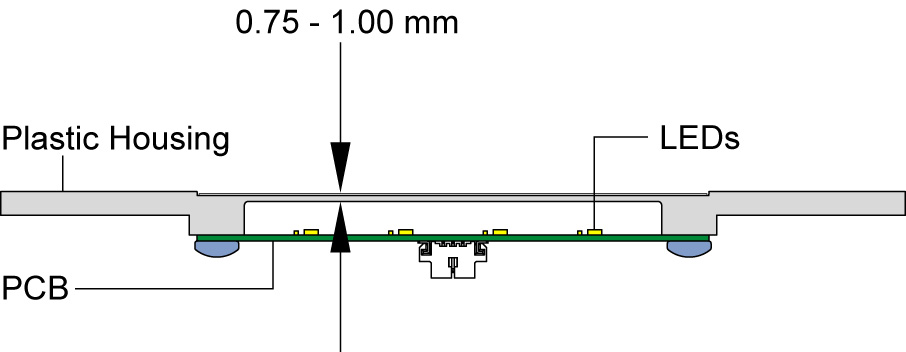

LED Deadfronts

Using LEDs to back light a logo or to create deadfronts for status is common in product design user interfaces and for lighting a logo or label.. In a recent project we used the plastic material of the housing to create the backlighting instead of adding a separate translucent part. In addition to eliminating the translucent part we wanted to maintain a single plane of material thickness for sealing out water, dust or dirt. Light is attenuated through plastic but by thinning the wall, light transmission can be adequate for most lighting needs. Under normal molding considerations a wall of 0.75mm to 1.00mm will be sufficient and feasible for manufacturing. Walls thinner than 0.75mm may short shot the part causing a hole in the material. Generous radii allow smooth transitions for the injection molded plastic to flow in the mold geometry.

7 June 2021

Tortoise's last mile delivery vehicle can be seen roaming the streets of Mountain View, California. EnMasse Design quickly developed working vehicles for the program, fabricating functional mockups, prototypes and initial production vehicles in a 6 month window. The remotely driven vehicle has a 200 pound payload with an 8 mph top speed. The vehicle can travel on sidewalks or bike lanes and arrives at its destination where customers access locking containers to retrieve their order of groceries or other goods.

8 January 2021

7 May 2019

Services Provided: Industrial Design, Mechanical Engineeering, concept design, rapid prototyping, detailed part design, material selection, injection molded part design, press and snap fits, graphics, CMF. 12 June 2018

Industrial Design work for Prescient Surgical (see our 1 May 2018 blog post below) won Bronze and Readers Choice Awards in the 2018 Medical Design Excellence Awards: http://mdeawards.mddionline.com/2018-winners 1 May 2018

Industrial Design work we did for a client was announced as a finalist in the 2018 Medical Design Excellence Awards: https://www.mddionline.com/mdea-er-and-or-tools-equipment-and-supplies

17 April 2018

How long should it take to get a quote? And how long should a client take to respond? The length of time it takes to receive a product development quotation depends on complexity of product, number of disciplines involved (Mechanical Engineering, Electrical, Industrial Design, Software) prior expertise in the specific product area as well as external factors. The firm may be busy or if a holiday is around the corner a quote may get delayed. Typically busy periods are months leading up to trade show design activity. For example, the months prior to CES in January are very busy for design firms providing consumer product design. Other factors may include the need for external manufacturing quotations.

Usually prior to a written quotation there is a client meeting to understand the effort, deliverables, schedule and budget. If the budget is not understood then the effort can’t be tailored to the client needs and the proposal will need to be revised. If time is important then honesty about the budget can be a time saver. Every proposal has to weigh time, cost, quality, risk, etc.

For a simple molded part design a quotation should take less than one week. Complex electro-mechanical products may require 2 weeks or more to allow time for various inputs from the required disciples (ME, ID, EE, Software). In larger businesses the legal team needs to weigh in on terms. For medical devices there also may be regulatory and quality inputs. Preparing quotations can be time consuming. We provide a comprehensive effort including time and materials expected to be required in various phases of the product development effort. We include meeting time as a percentage of the effort based on our historical averages. Estimates are also included for materials and prototypes to provide a comprehensive proposal. Material and prototype costs include hardware, 3D printing services, fabricated models, etc. Most clients prefer detailed estimates and like knowing their total outlay of costs. A quotation that lists only a minimal effort may make the initial cost more appealing, but beware of those types of proposals as the additional costs may lead to frustration during the development process as costs continue to rise beyond the initial estimate.

Decisions, decisions. How long should a client take to respond?

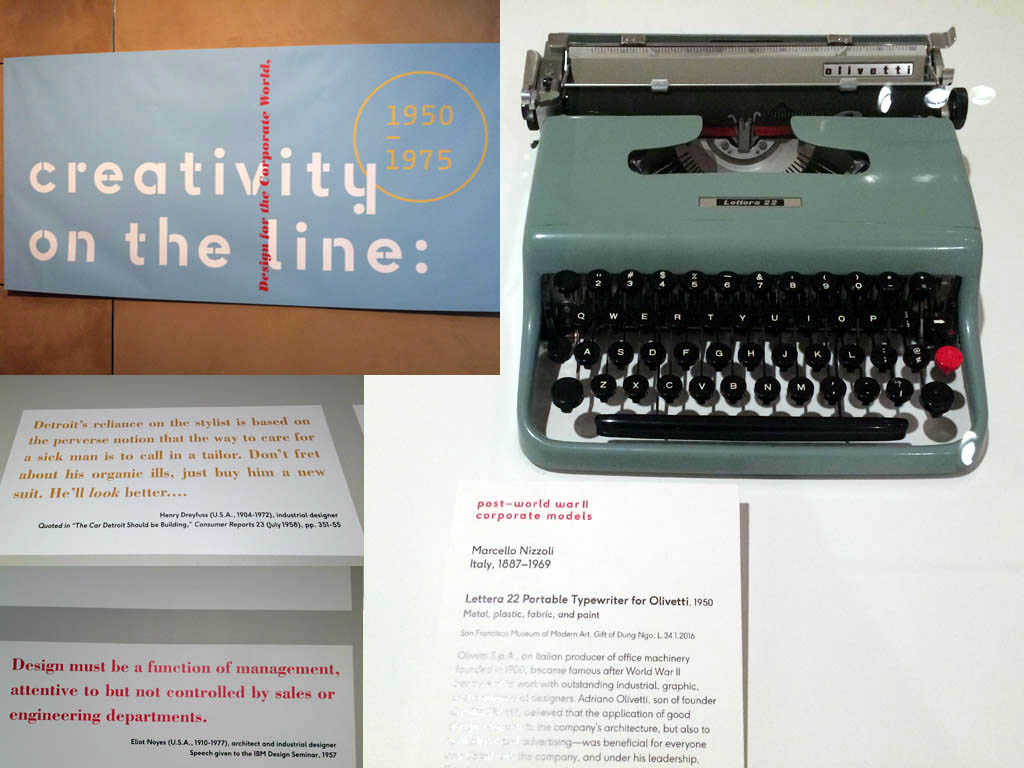

22 May 2017 Creativity on the Line - Design for the Corporate World at the Cantor Arts Center at Stanford University A small but enjoyable local exhibit on corporate Industrial Design in the 50s through 70s. http://www.museum.stanford.edu/view/Creativity.html

18 September 2015 Products That Last Summer is coming to a close and the rains are coming. In California this is wishful thinking as we’re in the midst of a severe drought. But it’s the time of the year for preventative home maintenance and my semi-annual climb to the roof of our house. I probably do this more than most as we have a flat roof and leaves and debris can build up more frequently with the minimal slope. I go up to sweep the leaves off the roof, clear the downspouts and check the skylights. In this occurrence I brought my caulking gun along to repair a small leak that I’ve known about in two of our three skylights. Our house was remodeled in 2006 and the skylights were installed correctly. Unfortunately, the seal around the glass deteriorated and small leaks developed after about 7 years. As I was climbing up the roof I noticed pieces of the dryer vent had fallen off and exposed the interior vent and sheetmetal. The flaps that normally close the vent were lying on the roof with other small cracked pieces. Initially I thought birds or squirrels had pried on the plastic vents and broken off the parts, but upon further examination I realized the material had just deteriorated. When I pushed on the housing it crumbled and numerous additional pieces fell to the roof shingles. This part was selected by my general contractor and was selected for external use. I confirmed this by looking at the manufacturers website - Deflecto and they claim the product is “durable weather resistant”. How can a product intended for its purpose fall apart after only seven years of normal use? The key factor on both the skylight seals and vent component is material selection. In both cases the manufacturer did not apparently look at product longevity during the manufacturing development and process. Exposure to sun, heat or cold can cause rapid wear to materials. For the repair of the skylight I chose a silicone caulk rated for high sun exposure and long life. I replaced the dryer vent with an all aluminum part from the same manufacturer, knowing that sun, heat or cold will not affect the product life. I expect the dryer vent to last the remaining life of the house. I’m not so sure about the skylight repair but I hope to find out in the coming months if we’re fortunate enough to get the needed rain. Understanding tradeoffs in material selection is an important aspect in product development. Whether the product is a dryer vent, skylight seal, consumer electronic housing that emits a lot of heat or a rugged portable enclosure we have the expertise to specify the correct materials for your project.

02 February 2015 Color Me Surprised As simple as color seems, it can be a complex and often perplexing task for novice developers. The human eye can discern millions of colors with very small differences between samples. Simply put - a plastic supplier may have hundreds or thousands of variations of even a white color for a single grade material. In addition to color the design team needs to consider opacity and texture along with the physical properties such as resin grade (perhaps for a medical device or food grade product). We request color chips from suppliers that have large databases of color using various standards including Pantone, RGB, LAB, CMYK and Federal Colors. Some of our favorite plastic suppliers offer resources to assist in color choices which include rankings of close matches to a desired color and standard and supply color chips for evaluation. Color chips usually have various areas of texture on a single plaque to allow visualization of color as it is affected by light dispersion. We review color under various conditions whether it be fluorescent, incandescent, halogen or sunlight. We like to allocate a reasonable amount of time for color development as well as receiving and evaluating color chips and textures. Large companies with exceptional design and quality control often have dedicated color and material designers who specify and track corporate colors - whether it be molded, painted or anodized parts. Once detailed design has been accomplished we provide drawings and specifications denoting material, grade, type and color numbers so complete quotations can be provided for all parts. Ensuring color has been specified correctly will allow the design and quotations of your molded parts to move through the process more efficiently.

02 September 2014 Understanding CAD File Formats and Deliverables

01 September 2014 NDAs and US copyright Laws

24 March 2014 To 3D (print) or Not to 3D (print) A topic that comes up fairly often in lunchtime conversation in our office is 3d printing. We often use a service provider for 3d prints (SLA, FDm, Objet, etc). We've often considered the tradeoffs of owning our own printer vs. using an outside service. Cost of ownership, repairs, quality, materials, labor to run and maintain and initial price have to be weighed before diving into one of these models. Some people in the industry have often said "why buy one when we can order parts and get them in a day or two?". While the delivery of parts can be as low as a day or two for local providers, we've also run into delivery delays as vendor queues get filled up (as CES approaches for example) or for other reasons (defective builds, courier delays and weather). After seeing prices on various models drop in recent years, we invested in a small FDM machine that can print ABS or PLA. The build size is limited but we find it works for over 50% of our projects in some aspect. We've found initial ideas can be tested quickly and rapidly at low cost. This benefits us as well as our clients. An idea can be developed in 3D and then printed later that day for evaluation. Iteration is also fast. For final parts we often go to a service bureau where they have machines with higher resolution or other materials. Another benefit we've found is the ability to produce a fixture much easier than having to machine it manually on a mill or lathe. This is the kind of unforeseen benefit we've really appreciated when owning one of these machines.

10 January 2014 Multiples in Design There's a large body of work on how design adds economic benefits related to product development and bottom line sales. I have not found much information on Venture Design and its economic implications for a design firm. What if your client asks you to work for stock? If you've been asked to trade a dollar of your rate for a dollar of stock is that a fair exchange? Essentially, you are working for a future value of what you can earn today. Why take $1 later when you can earn it today? The <5% reality Most start-ups fail. That is the reality. Venture capitalist investors hedge their risk because when they do profit, their return on investment is usually much more than 20:1. They exit at a time when they see benefit. If you are designing at the very early stage you are essentially like a founder or startup member. So why not get those rewards? If you do decide to risk design services for a venture make sure you understand your terms of the agreement - when you can sell, restrictions and a clear understanding of the company financials.

16 April 2013 Post Machined Anodizing for High- End Finish Post machined anodizing is often used on high end audio equipment and sometimes seen on automotive valve covers. We used this method to produce some cases for a client in the broadcast market. While the process does increase cost it gives a nice finish and contrasting color. Anodizing thickness varies by type and length of process. For our parts (Type II) the nominal anodizing thickness was 0.0015". The coating is then removed by machining. In this project about 0.0025" was sufficient to expose the underlying base material. The finish is also dependent on the location of the end mill used to remove the coating. For our parts we used the side of the end mill to remove material which gave it a nice consistent finish without tool marks. Some experimentation is involved and our machinist did a great job on this project.

15 April 2013 Apple-icious I've recently had more than a few customers request to mimic the manufacturing processes used by Apple. Specifically, machining a block of metal (usually aluminum) into a finely detailed case or housing. While this makes sense in some instances with the proliferation of CNC processes, Apple has taken it to a new level. They've invested a significant amount of money in numerous milling centers and incorporated finishing processes to meet their expectation of high quality. In some instances they've utilized technologies that are not common in the industry to achieve their design goals. For instance the LED window on Macbooks are actually very small holes that allow light to pass through the aluminum case. The holes are so small that it takes a laser to drill the holes for their high production rate requirement. A lot of my clients are startups with limited capital. Understanding the limitations and risks in choosing a manufacturing process are often understated in the initial design process. Choosing a design provider who can navigate the options to get to market are critical for small startups. We'll do our very best to be that provider.

About This Blog Founded in 2002, EnMasse Design is a small nimble design studio specializing in industrial design, product development and user interface design. We have experience in designing a range of products from small hand held devices to large systems. Our clients are usually startups and mid-cap companies where we engage a design process that utilizes observation, innovative thinking, and analysis. We have in-depth understanding for balancing design, engineering, manufacturing and technology. We're located in Mountain View, California in the heart of Silicon Valley. We're hopeful that some of the content here is interesting to our readers. We'll share stories of various projects that will explain our expertise, successes, problems identified and conquered.

About the Author I'm Jeff Gamelsky and have been a Product Designer for the last 30 years providing innovative product development for the medical, scientific, telecommunications and consumer industries. My areas of expertise include conceptual development, industrial design, user interface design, mechanical design and engineering, manufacturing and graphic design. This is my first time writing a blog. You can send me a message at jeff@enmassedesign.com

|